Additive Manufacturing, also known as 3D printing, has gone from a futuristic novelty to now a staple technological advancement. Additive manufacturing breaks the limits of traditional methods by changing the way the manufacturing industry creates and supports production parts.

When used correctly, additive manufacturing can deliver products with greater efficiency and improved performance. The advantages don’t stop there, however; there are financial advantages to 3D printing ranging from less product waste to better cost savings.

What is Additive Manufacturing?

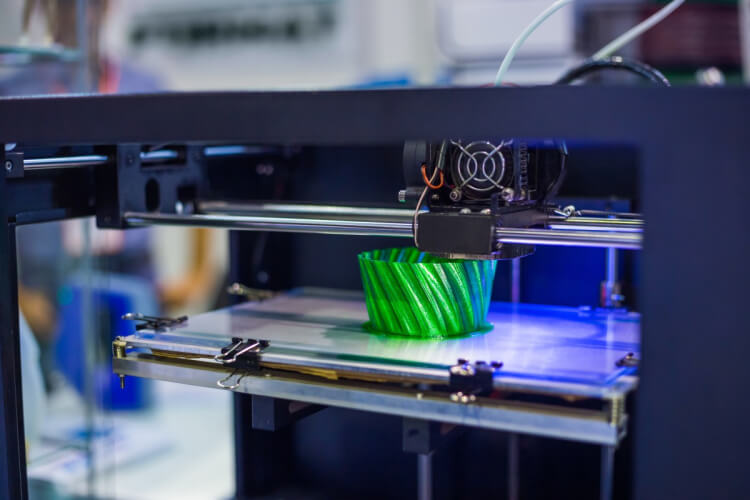

Additive manufacturing, or 3D printing, is a process that creates a tangible object from a digital design. While a traditional printer uses a computer to read a file and print out a flat, 2D replica on fabric or paper, 3D printing creates a physical object from a digital file, using layer after layer of material, until it forms a completed 3D image.

Additive manufacturing technologies build three-dimensional objects one superfine later at a time. Each subsequent layer bonds to the preceding later of partially melted material. Layering material can be a variety of substances, ranging from metal powder, ceramics, thermoplastics, glass, and even chocolate. As a result, 3D printers are not one-size-fit all types. There are many options for 3D printing, and so the type of printer ranges for different applications.

3D printing has been hailed for its innovative industrial manufacturing abilities, but not commonly for its money saving advantages. However, there are several cost saving advantages to 3D printing that make this manufacturing technology a valuable asset.

What are the Money Saving Advantages of 3D Printing?

There are multiple areas where the fiscal benefits of 3D printing manufacturing technology is evident, including:

Reduced Development Costs

This advanced manufacturing technique has the stereotype of being pricey, due to its initial cost price. However, the long-term reduced development costs yield money saving benefits.

In terms of machine operation costs, it depends on the size of the 3D printer. Most desktop 3D printers use as much power as a laptop, while industrial 3D printers use a significantly larger amount. Still, their ability to produce complex objects in a single step results in greater efficiency and productivity.

One of the main advantages of 3D printing is the reduced cost of labor. Besides post-processing, most 3D printers are self-sufficient and barely need assistance from an operator. The labor costs for a 3D printer are basically nonexistent, compared to traditional manufacturing where highly skilled operators are usually necessities.

Additionally, additive manufacturing at low volumes is competitive in cost compared to traditional manufacturing. It is significantly less expensive to 3D print prototypes rather than with other manufacturing methods, such as injection molding, traditional dies, molds, milling, and machining.

Less Product Waste

Additive manufacturing allows the creation of complex designs that are too difficult or too expensive to build using traditional manufacturing methods. Process development can be accomplished in less time with money spent on designing and building prototypes with traditional methods such as molds and dies. There is also less product waste from the need to scrap molds that need to be rebuilt. Since 3D printing only uses exact measurements of the materials needed, there is less time spent on producing unnecessary materials for specific parts.

By designing drafts in a computer program and then sending them to be printed, the time to create and produce new designs can be drastically shortened with less waste. This digital-to-digital process removes the additional intermediate steps of traditional prototyping. Additionally, 3D printing has increased turnaround. With the ability to create quick iterations, 3D printing identifies engineering flaws that may have taken weeks, if not months, to discover in traditional manufacturing. Fixes and adjustments can be made in a much more efficient manner than without additive manufacturing.

Decisions on final part designs can be achieved faster because the time required for effective design and creation is reduced. Overall, additive manufacturing offers a more effective and efficient design process with less waste and reduced spending.

Improved Quality of Products

The advantages of 3D printing extend into providing better quality product design and process development. Additive manufacturing allows manufacturers to produce superior products since flaws such as bad ergonomics can be identified earlier on and improved. As a result, the quality of the parts can be improved with a better final design with 3D printing.

Additionally, this technological advancement allows engineers to build complex and intricate parts that are not possible with other methods. Engineers are no longer restricted to the limitations of traditional manufacturing equipment; parts that needed added assembly and welding can now be created as a single part. This reduces waste and adds greater strength and durability to the product.

3D printing can also create materials out of a variety of different substances, such as thermoplastics. Some of these materials can substantially reduce weight while still maintaining strength and integrity. This can be exceptionally helpful when engineers want to maintain strength but reduce weight.

Additive manufacturing can be a valuable technology to create durable products that can maintain continuous use due to their improved quality.

Is Additive Manufacturing Right For Your Business?

3D printing has evolved significantly and can now be a valuable asset for rapid manufacturing processes.

Additive manufacturing allows for customization of their user’s needs. Whether it’s a large or small-scale project, there are numerous advantages of 3D printing that go beyond money saving. Choosing the right 3D printer is important for your manufacturing technology needs is important, however. Research the various 3D printing technologies available and find the additive manufacturing printer to reap the benefits of improved product quality and cost-reduction in manufacturing.